Jan Group produces high-performance conveyor belts for a wide

range of industries from mining, cement, quarries, metallurgy, recycling to

many other bulk-material handling industries. Jan heavyweight conveyor belts

keep your business running with exceptional performance, exceeding all

established international standards.

We remain true to the same principles on which our company was founded over

decades ago: providing superior service to our clients, putting safety first,

creating opportunities for our people, delivering exceptional work.

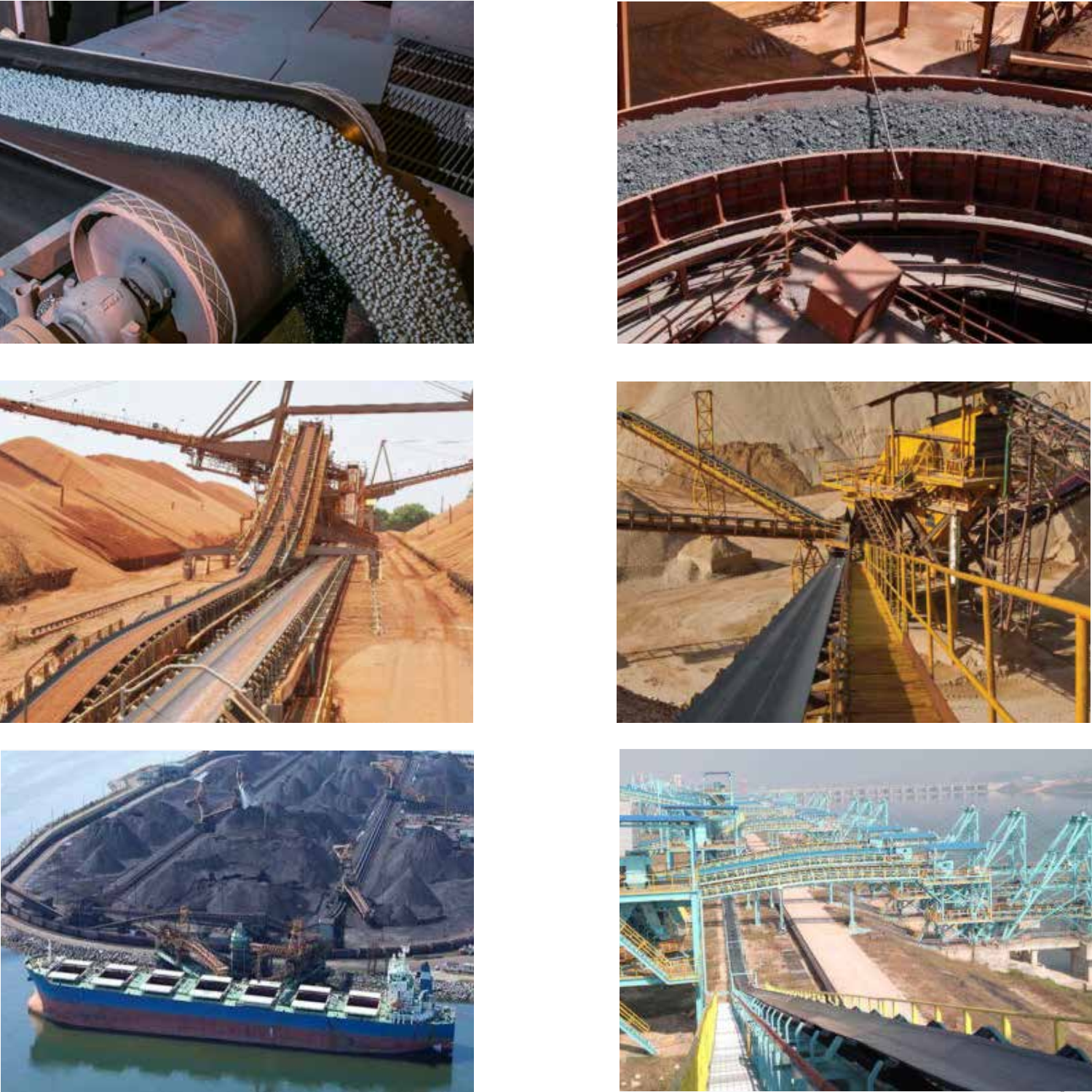

MINING

Open-pit mines

For most applications used in the open

air, Class 2A is adequate. Class 2A requires that the belt passes the ISO340.

The electrical conductivity of the belt also must fulfill the requirements of

ISO 284.

Underground mines

Underground mines are usually

characterized by their limited space and highly flammable

atmosphere. In addition to the tests done in our laboratory for the compliance

with ISO EN standard, special fire laboratory has been designed to test the

self-extinguishing properties of the belt when exposed to fire.

The fire resistance lab consists of the test devices suitable for the ISO EN

standard, which is referred to in many other standards. Further information can

be provided by our technical team, upon request.

Tunneling

Our belts are designed to handle the

transport of materials from tunnel excavation sites to the surface. Tunnels

have highly flammable work environment. Jan has been providing kilometers long

flame resistant belts in compliance with DIN14973 for the underground tunnel

industries.

Cement

Highly abrasive nature as well as the

high surface temperature of the transported materials enable cement industry

the most challenging one. These high temperatures accelerate the belts’aging

process and ends up with hardening or cracking of the belt surface, if not

chosen wisely. Our sales engineers make a questionnaire to make sure to offer

the best fitting product for the clients’ needs.

Steel

Metallurgy industry requires the

transport of heavy and sharp objects fallen from height or material becoming

trapped. That is why it is a challenging environment and global competition

forces companies to operate at the highest level of efficiency without the risk

of unexpected shutdowns. Our belts have been used by the steel industry for

years to convey materials like cokes and iron ore.

We have been providing the most

efficient products specific to steel application. We recommend impact resistant

belts and heat resistant belts that endure peak temperatures as high as 400

degree Celsius.

Aggregates

We have been providing belting solutions

for the transport of all materials in the aggregate industry including sand,

gravel, crushed rock, limestone and salt. Belts used in aggregate industry need

to have high resistance to impact, ripping, tear and abrasion loss to convey

heavy, sharp and extremely abrasive materials.

Ports

For on-site cargo transportation

conveyor lines are most commonly preferred due to the productivity and the cost

management. The choice of belting product is crucial since not only because the

structure of cargo packaging can cause abrasion loss in the belt surface but

also because of the hidden foreign objects that might tear the belt surface.

We provide impact and tear resistant

belting solutions that will endure sharp object impacts.

They are designed to guarantee safe and clean conveyor belt operations over

long distances and increased efficiency at transfer and unloading points.

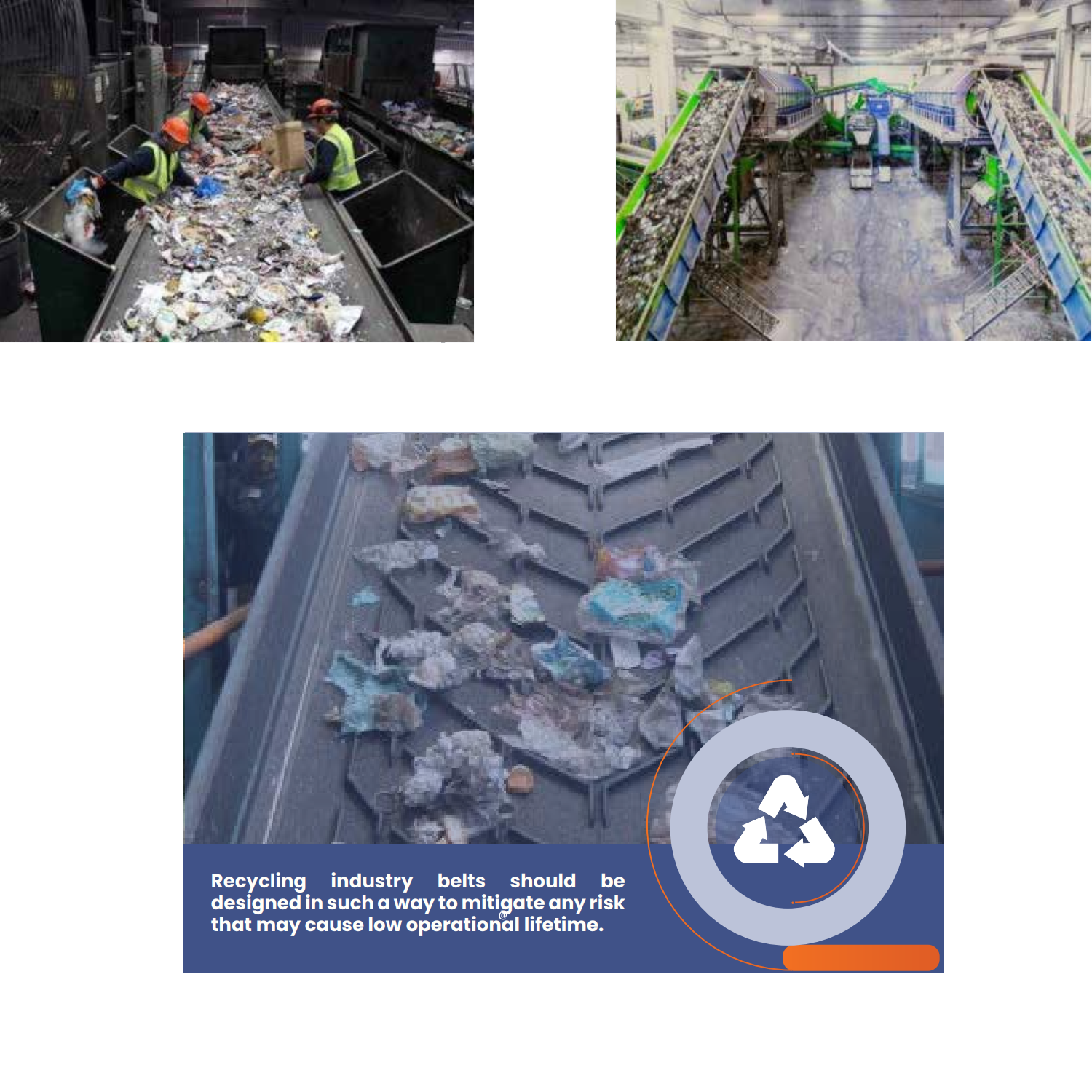

Recycling

Belts in recycling industry come across

with many materials of different nature. This industry transports large volumes

of material that varies greatly, from household waste and organic byproducts to

construction waste, the belt needs to overcome a lot of challenges.

Belts need to be chosen very carefully

as to withstand the abrasive nature of hard and sharp

materials being transported. Once these materials are trapped, they cause

irreversible damage on the conveyor line. In addition to the physical features

of the transported materials, the chemical content of these materials may

seriously damage the belt by causing cracks, swelling and distortion.

Risk of flammability and combustion should also be considered by choosing flame

resistant belts in this industry.